Service Hotline:+86-769-87938810

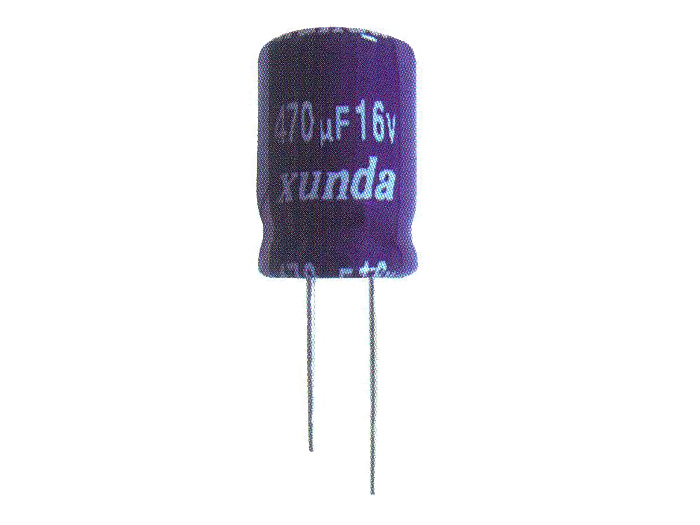

Aluminum electrolytic capacitors are commonly used components in electronic circuits, and their core function is to store and release electric charges through electrochemical principles. The following is a detailed analysis from two aspects: working principle and internal structure

I. Working Principle

Polarization and medium formation

The anode (positive electrode) of an aluminum electrolytic capacitor is made by electrochemical etching of high-purity aluminum foil to increase its surface area. Then, a voltage is applied in the electrolyte for anodic oxidation, forming a dense Al₂O₃ insulating layer on the surface (with a thickness of approximately the nanometer level). This oxide layer, as the dielectric (insulating layer), its insulating property and thickness directly determine the withstand voltage value and capacity of the capacitor.

Key features: The dielectric constant of Al₂O₃ is relatively high (~8-10), and combined with the rough surface structure after etching, it can achieve large capacity (μF to mF level) in a small volume.

Charge storage mechanism

When an external voltage is applied, the positive charges on the anode aluminum foil attract negative ions (such as OH⁻) in the electrolyte, forming charge separation on both sides of the Al₂O₃ layer and achieving energy storage.

The cathode (negative electrode) is usually an electrolyte or conductive polymer, and current is conducted out through another piece of aluminum foil (cathode foil).

Self-healing feature

If the dielectric layer is partially broken down, the electrolyte will re-oxidize at the fault point to form Al₂O₃, restoring insulation (but frequent breakdowns will shorten the service life).

Ii. Detailed Explanation of Internal Structure

1. Core components

Component materials and process effects

The anode aluminum foil is made of 99.9% high-purity aluminum. After etching, it forms a porous structure (increasing the surface area by 50 to 200 times), which enlarges the electrode area and enhances the capacity

Cathode aluminum foil is common aluminum foil, and its surface may be coated with carbon or conductive polymers to collect current and form a circuit with the electrolyte

Electrolytes such as ethylene glycol/boric acid and conductive salts (such as ammonium salts) or solid conductive polymers (such as PPy) provide ionic conductive pathways and participate in the repair of the oxide layer

The cellulose or synthetic fiber diaphragm of the electrolytic paper isolates the two-pole foil and adsorbs the electrolyte

The shell is made of aluminum or resin and is encapsulated. There is an explosion-proof valve (liquid electrolyte type) on the top to seal and release the internal pressure, preventing explosion

2. Typical structural sections

Aluminum shell (cathode connection

├─ Cathode aluminum foil (lead-out wire)

├─ Electrolytic paper (impregnated with electrolyte)

├─ Anode aluminum foil (Al₂O₃ layer, lead wire)

└ - Rubber sealing plug (leak-proof)

Iii. Key Parameters and Characteristics

Polarity requirements

The positive and negative poles must be connected correctly. Reverse voltage can cause the oxide layer to dissolve, generating gas that may lead to bulging or even explosion.

Equivalent circuit model

Ideal capacitance (C) + equivalent series resistance (ESR, caused by electrolyte/foil resistance) + leakage current (μA level).

Temperature and Lifespan

The electrolyte is volatile (liquid form), and its lifespan decreases exponentially at high temperatures (for example, the lifespan of the 105℃ type is usually 2000 to 5000 hours).

Frequency response

The high-frequency performance is relatively poor (due to ESR and inductance effects), and it is suitable for low-frequency filtering (such as power rectification).

Iv. Liquid vs. Solid Electrolytic Capacitors

Type: liquid electrolyte, solid conductive polymer

The ESR is relatively high (10-100 M Ω) and extremely low (<10 M Ω

The lifespan is longer due to the drying up of the electrolyte (non-volatile)

The withstand voltage can reach 600V and is usually ≤100V

Application scenarios: High-voltage and large-capacity (such as power filtering), high-frequency and low-ESR requirements (such as CPU power supply)

V. Failure Modes

Capacity attenuation: Caused by the evaporation of the electrolyte or the aging of the oxide layer.

Elevated ESR: Electrolyte drying up or polymer degradation.

Short circuit/leakage: Dielectric layer rupture or seal failure.

From the above analysis, it can be seen that the performance of aluminum electrolytic capacitors is highly dependent on material processing and electrochemical design. Engineers need to weigh and choose based on circuit requirements (capacity, withstand voltage, ESR, temperature).