Service Hotline:+86-769-87938810

In power circuit design, the selection of aluminum electrolytic capacitors directly affects the stability, lifespan and cost of the circuit. The following are the key selection steps and precautions, summarized based on engineering practice:

I. Steps for Selecting Core Parameters

1. Determine the voltage level

Rated voltage (V_R) :

Select a voltage ≥1.5 times the actual working voltage (for example, if the circuit voltage is 12V, choose the 25V model).

In high-voltage scenarios (such as PFC circuits), a larger margin (≥2 times) should be reserved.

Note: Excessively high rated voltage will increase volume and cost.

2. Calculate the required volume value

Input filter capacitor (after rectification) :

C = Iload2 ⋅ f ⋅ ⋅ ⋅ f Δ VC = 2 Δ VIload

Iload: Load current; ff: Ripple frequency (power frequency rectification is 100/120Hz); ΔVΔV: Allowable ripple voltage.

For example: 1A load, 100Hz, the ripple requirement is 1V → C≈5000μF, and FC≈5000μF.

Output filter capacitor (DC-DC) :

The capacitance value may be lower but a lower ESR model is required in combination with the switching frequency (such as 100kHz) and ESR requirements.

3. Evaluate the ripple current capability

Ripple current (I_RMS) :

Calculate the actual ripple current in the circuit (measured by an oscilloscope or simulated).

Select the rated ripple current of the capacitor greater than the actual value and take into account the high-frequency attenuation (the manufacturer provides the frequency correction factor).

Parallel connection of multiple capacitors: It can share the ripple current and reduce the individual pressure.

4. Temperature and lifespan considerations

Temperature derating

For every 10℃ decrease in actual working temperature, the service life doubles (refer to the Arrhenius model).

Choose the 105℃ model (which has a longer lifespan than the 85℃ model and can be used even at low temperatures).

Lifespan formula

L=L0⋅2T0−Ta10⋅(IratedIactual)2L=L0⋅210T0−Ta⋅(IactualIrated)2

L0L0: Nominal life (e.g. 2000 hours at 105℃), TaTa: Actual operating temperature.

Ii. Key Feature Matching

1. ESR (Equivalent Series Resistance

High-frequency applications (such as switching power supplies) : Select low ESR models or solid-state aluminum electrolysis.

The relationship between ESR and heat generation: Ploss=IRMS2⋅ESR PLOSS =IRMS2⋅ESR Overheating will accelerate failure.

2. Dimensions and installation methods

Diameter/height limit: Check the PCB space (e.g. φ8mm vs φ10mm).

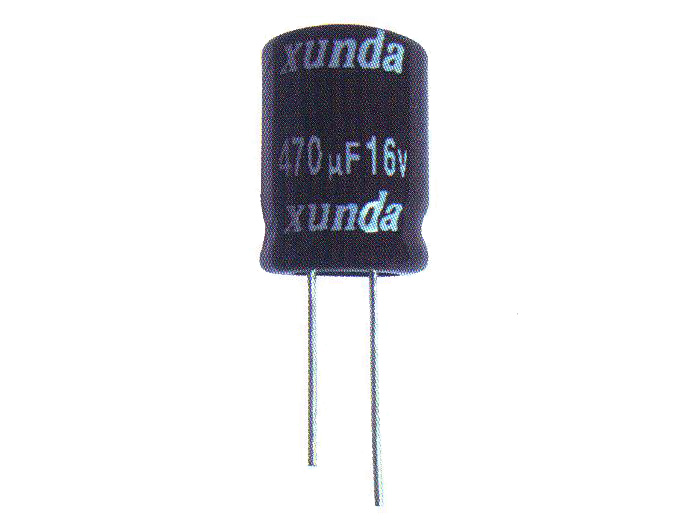

Pin types: Radial leads (through-hole), surface mount type (such as SMD aluminum electrolytic).

Iii. Optimization of Application Scenarios

1. Input filtering (power frequency rectification

Recommended model: High capacity, common ESR (such as the KXG series of Nippon Chemi-Con).

Capacity priority: Mainly to suppress low-frequency ripple.

2. Output filtering (DC-DC Buck/Boost)

Recommended model: Low ESR, good high-frequency characteristics (such as Panasonic's FM/FR series).

Parallel combination: Large capacitance aluminum electrolytic + small capacitance ceramic capacitor (covering the entire frequency band).

3. High-temperature environments (such as automotive electronics)

Selection: 125℃ heat-resistant models (such as Rubycon's ZLH series).

Avoid: Place near heat sources (such as inductors, MOSFETs).

Iv. Reliability Design Techniques

Reverse voltage protection: Aluminum electrolysis has extremely poor resistance to reverse voltage (usually less than 1V), and a reverse connection protection circuit is required.

Vibration environment: Select models with rubber pads at the bottom (such as Nichicon's UHW series).

Life redundancy: Select the critical power circuit at twice the calculated life.

V. Quick reference of Manufacturer models

Features of the Application requirement recommendation series (Examples)

General low-cost Nichicon UVR 85℃ reference material

Long life, low ESR Panasonic FM/FR 105℃, suitable for high frequency

High-temperature automotive-grade Rubycon ZA/ZLH 125℃, anti-vibration

Solid-state alternative NCC (Chemi-Con) PSA series conductive polymers, with ultra-low ESR

Vi. Verification and Testing

Actual ripple measurement: Use an oscilloscope and a current probe to verify whether the temperature rise of the capacitor exceeds the standard.

Aging test: After accelerated aging in a high-temperature chamber (such as 105℃ for 1000 hours), detect the change in capacitance value /ESR.

Pitfall Avoidance tips

Avoid excessive capacitance causing charging Inrush current (Inrush) to damage the rectifier diode.

When changing the model, the ESR and ripple current need to be re-evaluated (the difference among different brands can be up to 30%).